Showroom

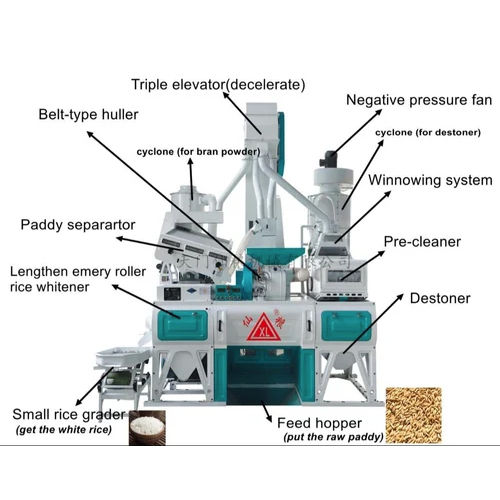

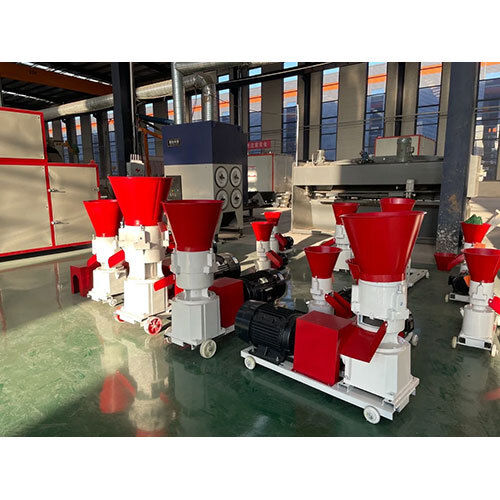

Leveraging on a skilled workforce and ethical business policies, we trade and supply Industrial Machinery. These products are manufactured using finest quality components and other material following industry standards & norms. In compliance with international quality standards, these products are applauded for their immaculate performance, longer service life, robust construction and minimal maintenance cost. Industrial Machinery can be availed from us in various specifications at competitive rates.

The term "industrial machinery" refers to a broad category of mechanical tools used in manufacturing, construction, and other industrial operations. These devices are precisely designed to carry out specific tasks.

We have Manufacturer, Supplier, and Exporter of high-quality Food Processing Machinery available in wide range. For more specification about Food Processing Machinery, Please send the inquiry.

We are a reputable organization which deals in providing high quality products. The term "food processing machinery" refers to a broad range of tools used to turn unprocessed agricultural resources into finished, packaged foods.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese