Compressed Air Dryer

110000 INR/Piece

Product Details:

- Usage Industrial

- Color Blue

- Product Type Compressed Air Dryer

- Condition New

- Power Source 220/415 V

- Voltage 220/440 V Volt (v)

- Motor 2 HP

- Click to View more

X

Compressed Air Dryer Price And Quantity

- 110000 INR/Piece

- 1 Piece

Compressed Air Dryer Product Specifications

- 12 months

- 220/415 V

- 2 HP

- 220/440 V Volt (v)

- Blue

- Compressed Air Dryer

- Industrial

- New

Compressed Air Dryer Trade Information

- 7-10 Days

Product Description

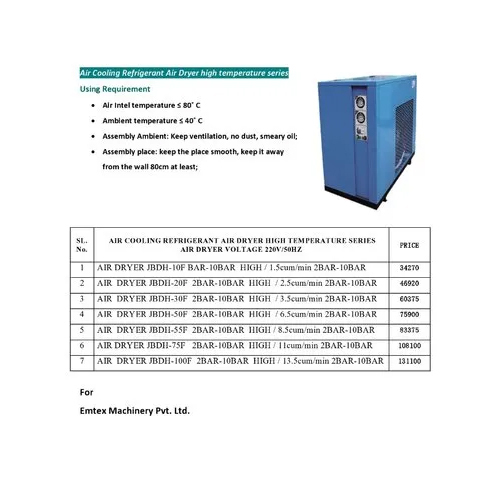

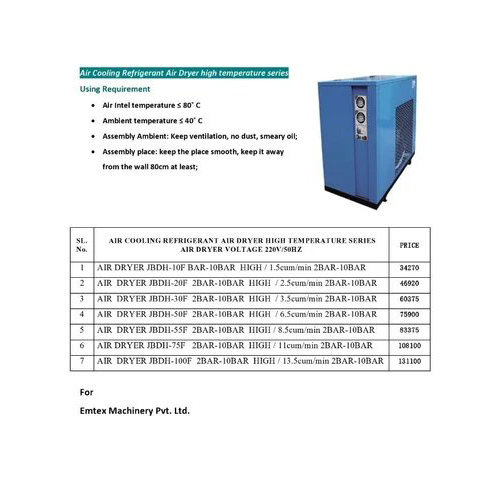

A device called a compressed air drier is used to remove moisture and humidity from compressed air. Modern applications often use compressed air, which includes water fume that can condense into fluid water as the air cools. Compressed air dampness can cause a variety of problems, including erosion, damage to equipment, and lowered item quality during assembly procedures. By lowering the compressed air's dew point and effectively removing moisture content, compressed air dryers can prevent these problems.

| Automation Grade | Automatic |

| Voltage | 220 V |

| Dryer Type | Refrigeration Dryer |

| Phase | Single Phase |

| Dryer Horse Power | 2 HP to 100 hp |

| Dryer Technology | Refrigerated |

FAQs of Compressed Air Dryer:

Q: What is a compressed air dryer?

A: A compressed air dryer is a mechanical gadget intended to eliminate dampness and stickiness from compressed air, guaranteeing dry and clean air for different modern applications.

Q: For what reason is dampness expulsion significant in compressed air?

A: Dampness in compressed air can prompt consumption, harm to pneumatic devices and hardware, and issues in assembling processes. Eliminating dampness keeps up with gear proficiency and item quality.

Q: What sorts of compressed air dryers are accessible?

A: There are various sorts of compressed air dryers, including refrigerated dryers, desiccant dryers, layer dryers, and that's just the beginning. Each type has its own strategy for eliminating dampness.

Q: How does a refrigerated compressed air dryer work?

A: A refrigerated dryer cools the compressed air, making water fume gather into fluid water, which is then eliminated from the air stream. The cooled and dried air is then warmed prior to entering the framework.

Q: What is a desiccant compressed air dryer?

A: A desiccant dryer utilizes a drying specialist (desiccant material) to retain dampness from the compressed air. There are two pinnacles loaded up with desiccant, one drying the air while the other is being recovered.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese