Industrial Screw Air Compressor

Product Details:

- Color Black

- Usage Industrial

- Product Type Screw Air Compressor

- Condition New

- Motor 7.5 to 100 HP

- Click to View more

Industrial Screw Air Compressor Price And Quantity

- 1 Unit

- 110000 INR/Unit

Industrial Screw Air Compressor Product Specifications

- Black

- 7.5 to 100 HP

- Industrial

- Screw Air Compressor

- New

Industrial Screw Air Compressor Trade Information

- 10 Unit Per Month

- 10 Days

- All India

Product Description

An air compressor that uses a rotating positive dislodging device to pack air is known as a screw air compressor, sometimes known as a rotating screw compressor. In contemporary and commercial applications, screw air compressors are typically used to provide a never-ending supply of compressed air for various cycles and hardware.

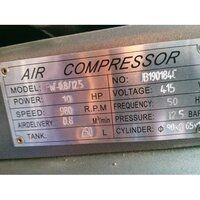

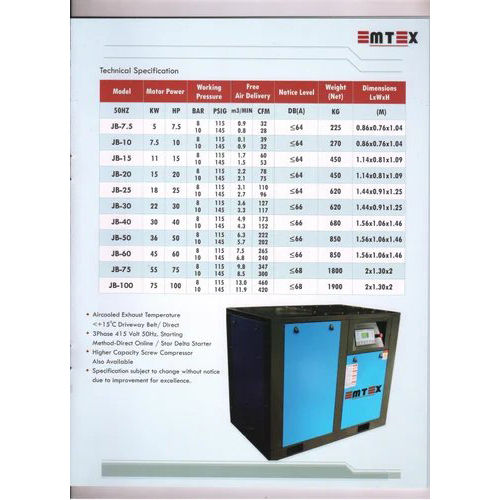

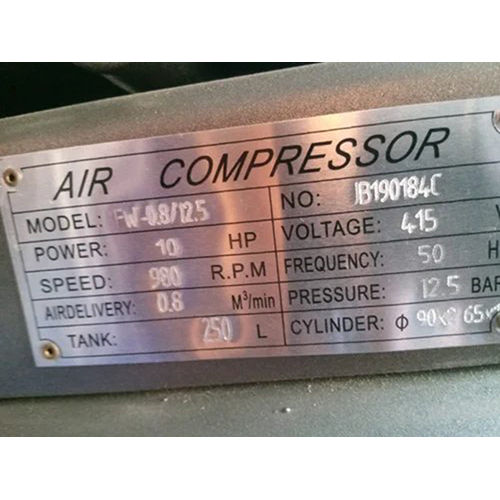

| Compressor Technology | Screw Compressor |

| Discharge Pressure | 8 to 10 BAR |

| Maximum Flow Rate | 33 to 420 cfm |

| Compressor Brand | Emtex Machinery |

| Horse Power | 7.5 to 100 HP |

| Usage/Application | Industrial |

| Power Source | AC Three Phase |

| Cooling Method | Air Cooled |

| Compressor Noise Level (Db) | 64 to 68 |

| Warranty | 1 Year |

| Frequency | 50/60 Hz |

| Voltage | 220/415 V |

| Material | MS |

| Weight | 225 to 1900 Kg |

FAQs of Screw Air Compressor:

Q: What is a screw air compressor?

A: A screw air compressor is a mechanical gadget that utilizes a pair of pivoting screws or rotors to pack air, bringing about a constant inventory of compacted air.

Q: How does a screw air compressor work?

A: Screw air compressors utilize two helical rotors, frequently alluded to as male and female rotors, that turn in inverse bearings. As the rotors turn, air is brought into the compressor's chamber and steadily compacted as the rotors network together.

Q: What are the benefits of utilizing a screw air compressor?

A: Screw air compressors are known for their high effectiveness, constant activity, unwavering quality, and capacity to give a consistent progression of packed air.

Q: What are the principal parts of a screw air compressor?

A: The primary parts incorporate the rotors, air channel and outlet ports, oil separator, oil cooler, air channels, and control framework.

Q: Are there various sorts of screw air compressors?

A: Indeed, screw air compressors can be classified into oil-infused and sans oil types. Oil-infused compressors use oil for fixing and cooling, while sans oil compressors depend on different techniques to accomplish comparable outcomes.

Q: What is the average scope of limit with respect to screw air compressors?

A: Screw air compressors come in different sizes and limits, going from little units reasonable for studios to huge units utilized in modern settings.

Q: How is support taken care of for screw air compressors?

A: Support incorporates ordinary checks and substitutions of channels, oil, and other consumables, as well as occasional reviews of the compressor's parts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese