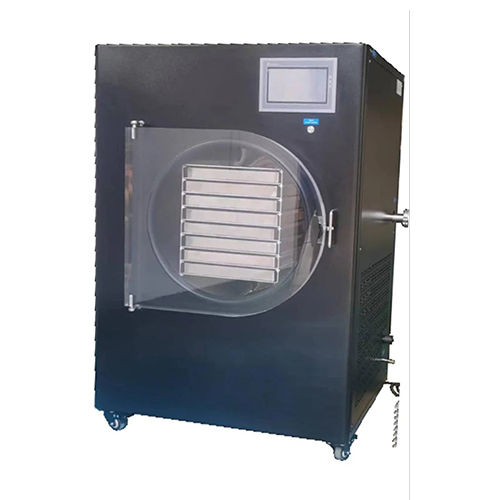

Commercial Freeze Dehydrator

Price 550000 INR/ Piece

Commercial Freeze Dehydrator Specification

- Product Type

- Commercial Freeze Dehydrator

- Power Source

- Electricity

- Operating Type

- Automatic

- Power

- 2200 Watt (w)

- Dimension (L*W*H)

- 810*730*1180 mm Millimeter (mm)

- Weight (kg)

- 140 Kilograms (kg)

- Color

- Blue

- Usage & Applications

- Industrial

Commercial Freeze Dehydrator Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 10 Days

About Commercial Freeze Dehydrator

Overview of the Freezer Dehydration Machine

The Freezer Dehydration Machine is a sophisticated appliance designed for food preservation through freeze-drying, or lyophilization. This method involves freezing the food and subsequently reducing the surrounding pressure, enabling the frozen water to transition directly from solid to gas, bypassing the liquid phase.

Product Description

Purpose

This machine is expertly crafted to extend the shelf life of a variety of foods by removing moisture while preserving their structural integrity, flavor, and nutritional value. It effectively retains fruits, vegetables, meats, and ready-to-eat meals, producing lightweight, shelf-stable products that can be rapidly rehydrated.

How It Works

- Freezing: The process starts by freezing the food at extremely low temperatures, typically below -40oC (-40oF), which helps maintain cellular structure.

- Primary Drying (Sublimation): After freezing, a low-pressure environment is created, allowing the ice within the food to sublimate directly into vapor, thus removing most moisture.

- Secondary Drying (Desorption): The machine then gently heats the food to remove any remaining bound moisture, ensuring optimal preservation.

- Packaging: Once dehydrated, the food is sealed in airtight containers or vacuum-sealed bags to prevent moisture reabsorption.

Features

- Advanced Temperature Control: Allows for precise adjustments tailored to different food types, optimizing the freeze-drying process.

- Vacuum System: A powerful vacuum pump establishes the low-pressure conditions essential for effective sublimation.

- Multiple Trays: The machine includes several trays, enabling simultaneous freeze-drying of various items.

- User-Friendly Interface: Digital controls simplify operation, allowing users to monitor temperature, pressure, and drying progress easily.

- Stainless Steel Construction: Built from high-quality materials that are durable and easy to maintain.

Applications

- Home Preservation: Ideal for families wishing to store garden produce, bulk purchases, or prepare for emergencies with long-lasting, nutritious meals.

- Food Industry: Widely used to produce shelf-stable ingredients and snacks, such as freeze-dried fruits, vegetables, and coffee.

- Camping and Outdoor Activities: Perfect for creating lightweight meals that are easy to carry for hiking, camping, or emergency kits.

- Scientific and Medical Use: Utilized in laboratories for preserving biological samples, pharmaceuticals, and other sensitive materials.

Benefits

- Long Shelf Life: Properly stored freeze-dried foods can last 25 years or more, making them ideal for emergency preparedness.

- Nutrient Retention: The process preserves a significant portion of vitamins, minerals, and enzymes, ensuring nutritional quality.

- Preserved Flavor and Texture: Foods retain their original taste and texture upon rehydration, unlike other drying methods that may alter them.

- Lightweight and Portable: The removal of moisture greatly reduces weight and storage needs, facilitating transport.

- No Refrigeration Required: Freeze-dried foods are shelf-stable and do not necessitate refrigeration, conserving energy and space.

| Material | Stainless Steel |

| Automation Grade | Digital Control |

| Machine Power | 2200 W |

| Voltage | 220 V |

| Frequency | 50 Hz |

| Phase | Single Phase |

| Dimensions LxWxH | 810*730*1180 mm |

| Weight | 140 kg |

| Tray Size. | 265*435*30 mm |

| Gross Weight | 230 Kg |

| Packaging Size | 840*830*1520 mm |

| Capacity. | 10-12 kg |

| Drying Area | 0.92 m3 |

| Noise Level | 60dB |

| No of Tray | 8 |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dehydrator Machine Category

Solar Dehydrator For Fruit And Vegetable

Price 7500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Solar Dehydrator For Fruit And Vegetable

Power Source : Electricity

Usage & Applications : Industrial

Operating Type : Automatic

Food Freeze Dehydrator

Price 450000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Food Freeze Dehydrator

Power Source : Electricity

Usage & Applications : Industrial

Operating Type : Automatic

Solar Dehydrated Machine

Price 52000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Other, Solar Dehydrated Machine

Power Source : Electricity

Usage & Applications : Industrial

Operating Type : Automatic

Durable and reliable food dehydrator

Price 40500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other

Power Source : Electricity

Usage & Applications : Industrial

Operating Type : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese