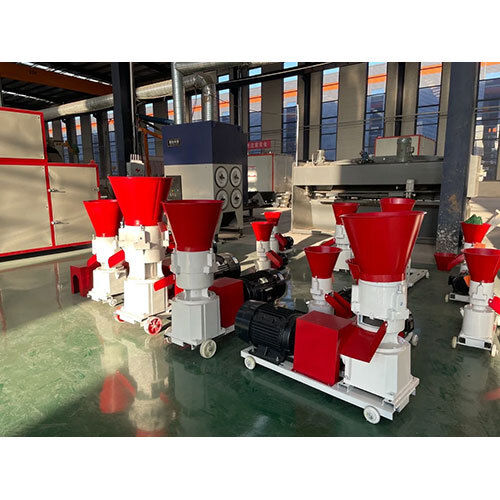

Biomass Pellets Making Plant

Price 1100000 INR/ Unit

Biomass Pellets Making Plant Specification

- Product Type

- Biomass Pellets Making Plant

- Power Source

- Electricity

- Operating Type

- Automatic

- Weight (kg)

- 1400 Kg Kilograms (kg)

- Production Capacity

- 600-800 Kg/hr. Kg/hr

- Usage & Applications

- Industrial

Biomass Pellets Making Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 10 Days

About Biomass Pellets Making Plant

The Biomass Pellets Making Plant offers an innovative and effective way to convert various organic materials into high-density fuel pellets. This machine is suitable for both industrial and smaller-scale operations, capable of processing a wide range of feedstocks such as wood chips, sawdust, straw, rice husks, bamboo, palm kernel shells, and other agricultural byproducts.

Key Features:

- High Efficiency: Powered by a robust motor and advanced compression technology, this machine enhances throughput while ensuring optimal pellet density.

- Durable Construction: Built with high-quality stainless steel and alloy components, it is designed for long-lasting performance in challenging environments.

- User-Friendly: Its intuitive controls and straightforward interface make it easy for operators of any experience level to manage.

- Versatile Production: Capable of creating pellets in various sizes, it caters to different applications, including heating, energy generation, and animal bedding.

- Environmentally Friendly: By converting waste materials into renewable energy, it helps minimize environmental impact and supports sustainable energy initiatives.

- Safety Features: The machine includes overheat protection, automatic shutdown, and safety guards to ensure secure operation.

Perfect for biomass energy facilities, agricultural processing plants, pellet fuel production lines, and farms, the Biomass Pellets Making Plant enhances the value of organic waste while contributing to a cleaner, greener energy landscape.

Invest in sustainable energy with the Biomass Pellets Making Plant-your partner in efficient and eco-friendly fuel production!

| Automation Grade | Automatic |

| Briquette Size | 6/8/10 mm |

| Power Required | 55 Kw |

| Frequency | 50 hz |

| Dimension | 178*85*174 Cm |

| Voltage | 415 V, Three Phase |

| Weight | 1400 Kg |

| Capacity. | 600-800 Kg/hr. |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Biomass Pellet Machine Category

Biomass Fuel Pellets Making Machine

Price 700000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : Industrial

Weight (kg) : 870 Kg Kilograms (kg)

Product Type : Other, Biomass Fuel Pellets Making Machine

Dimension (L*W*H) : 142*61*156 Cm Centimeter (cm)

Automatic Biomass Pellets Making Machine

Price 4000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Usage & Applications : Industrial

Weight (kg) : 320 Kilograms (kg)

Product Type : Other, Automatic Biomass Pellets Making Machine

Dimension (L*W*H) : 105*60*134 Cm Centimeter (cm)

Biomass Wood Pellets Machine

Price 415000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : Industrial

Weight (kg) : 500 Kg Kilograms (kg)

Product Type : Other, Biomass Wood Pellets Machine

Dimension (L*W*H) : 123*61*140 Cm Centimeter (cm)

Biomass Pellets Machine

Price 158000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : Industrial

Weight (kg) : 206 Kg Kilograms (kg)

Product Type : Other, Biomass Pellets Machine

Dimension (L*W*H) : 84*46*90 Cm Centimeter (cm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese